Our Company is well equipped with latest facilities for manufacturing quality casting from 10 Kgs. to 1500 Kgs. Further capacity in addition for 3M.T.

Pattern Shop

Our Pattern Shop and ancillaries are well equipped for manufacturing wooden and aluminum patterns.

Centrifugal Casting

We are having vertical centrifugal casting machine having 300 Kgs to 2500 Kgs per pc weight capacity of Gibson U.K. (England) Model VBT-4.

Power

We have standby power upto 1250 KVA D.G.Sets for uninterrupted power supply.

Melting Section

Our melting section consist of medium frequency furnace with 100,500,750, 300 Kgs. Crucible capacity. and 1 No. 500 Kg. Rotary Furnace with recuperator. 750KW / 500HZ VIP Power TRAK-R-PI with two 1500Kg. Duraline Furnace.

Fettling

Our fettling section is capable of 200 M.T output per month and is fully equipped with swing grinders 12" & 16" dia and GQ-6, rotofettle flexible shaft grinders, Pneumatic chippers, welding machines and Gouzing machine. Shot blasting machine having capacity 1 Ton per batch.

Machine Shop

Our in house machine shop is well equipped with 1700Ø & 1400Ø Vertical Turret Lathe Machines, heavy duty, medium duty lathe machines, drilling machines, planner and shaping machine with overhead crane. Vertical Boring Machine Double Table Ø12", Make : "NEWALL" U.K.

Our ancillaries machine shop are also well equipped with boring, turning, planning, shaping and drilling machines.

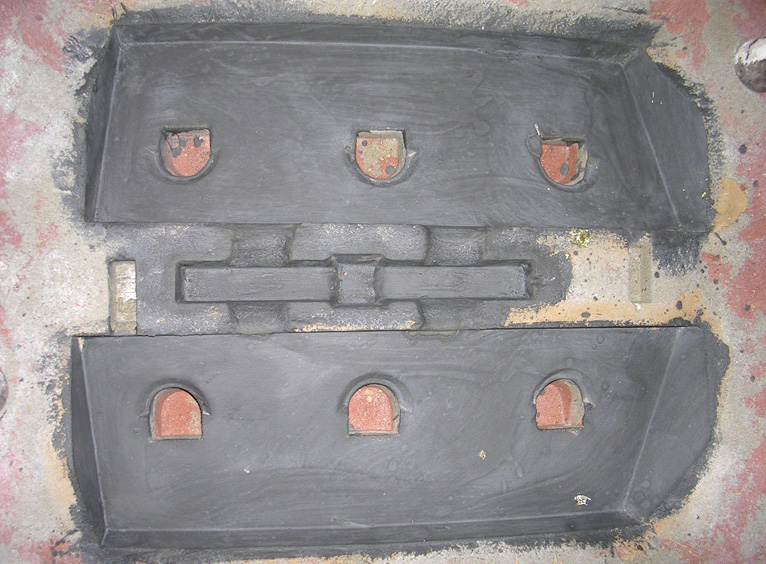

Moulding Section

Our molding section is equipped with 2 nos. High Pressure moulding machine of GISAG BAUKEMA (GERMANY), 2 Ton & 1 Ton knock out machine, 2 Nos. Air Compressor CH - 200 CFM KG/CM2, HORIZON SERIES ENERGY efficient screw Air Compressor 191 CFM, 4 nos Sand Mix Muller with 500 / 750 kgs. Capacity, 4 nos. CP Pneumatic Hammers and 1 no. mould hardness tester. We have CO2, green sand and Nobake process and shell moulding castings can be offered, "IMF" Automatic Sand Plant Two Part System 10 Tons/Hour being added towards capacity enhancement.